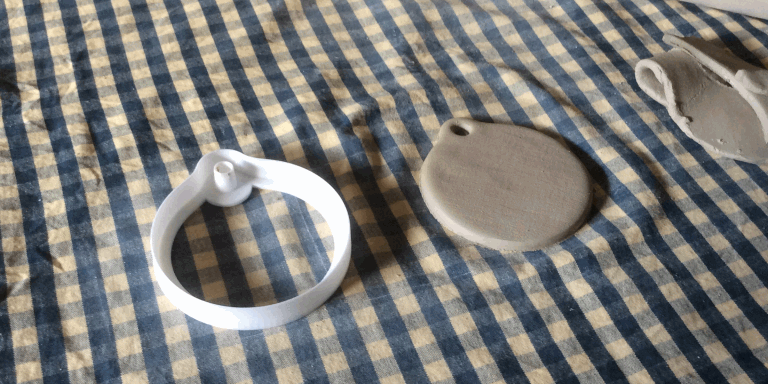

Another clay cutter was needed, simpler than before, but benefiting from the learning curve. A new feature was the cutting of a hole.

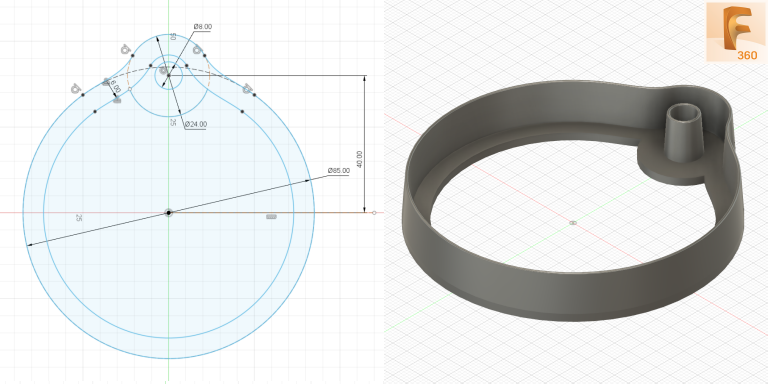

3D modelling

As before, in Autodesk’s Fusion 360, the profile of a cutting edge was swept around a boundary curve. The profile was narrower (built on a 2.4 mm square, rather than a 3.2 mm square) and taller (about 15 mm) than before. The hole would have a diameter of 8 mm and be at least 8 mm from the edge of the clay.

As before, rigidity was provided by extruding a base profile. The base was thinner (2.4 mm, rather than 3.2 mm) and offset closer to the boundary (6 mm, mostly) than before.

The resulting body was saved as an STL file, imported into Cura 4.6.1 and sliced with the draft setting (layer height 0.2 mm) and 15% infill density. Cura estimated that it would take about an hour to print (to be taken with a pinch of salt) and use 3.9 m of filament.

Cutting

There were signs that the PLA may have been affected by being out in the air for almost a year: the filament has become brittle and snapped between prints; and there was a little stringing where none would be expected (although perhaps a temperature of 210° is a little too high). However, the printed cutter performed as planned.